Methylal has excellent physical and chemical properties, good solubility, low boiling point and good water solubility. Therefore, it can be widely used in cosmetics, pharmaceuticals, household products, industrial automotive supplies, pesticides, leather glazing agent, detergent, rubber industry, paint, ink and other products. At the same time, methylal has good degreasing ability and volatility, and can be used as a cleaner to replace F11 and F113 and chlorine-containing solvent, replacing freon, reducing the emission of volatile organic compounds (VOCs) and pollution to the air.

High concentration of methylal is mainly used in molecular weight regulator produced by paraformaldehyde, plasticizer of resin, hypnotic, analgesic, perfume and high-grade cosmetics, solvents for Grignard reaction and Reppe reaction, etc.

As a formaldehyde derivative, methylal has a wide market demand; especially high concentration methylal has a great market application and high added value.

Methylal process of Dolton has been widely recognized as low consumption, good quality and stable operation.

By many years practice, Dolton has developed a new process technology with independent intellectual property rights; The catalyst regeneration and replacement is convenient, and the conversion rate and output are further improved. The COD content in wastewater is reduced to below 200ppm.

Methylal product is enriched on top of the column while the recombinant is extracted from the bottom. At the top of the column, the methylal condenses in the condenser and flows into the reflux tank, partial reflux for column top, part extracted as product.

Dolton provides three process solutions to meet different regional product standards and sewage discharge standards.

Methylal process flow chart in column 1

Methylal process flow chart in column 2

External methylal process flow chart

High methylal concentration

High concentration methylal process flow chart with 2 columns

High concentration methylal process flow chart with 3 columns

2, The catalyst has a long activity time and can be regenerated.

3, The waste water quantity is small and the formaldehyde content is lower than the environmental requirements and energy saving, greatly reduces the sewage discharge.

4, It has the advantages of high conversion rate, good selectivity, low energy consumption, high product purity, easy operation and small investment.

Main raw material consumption

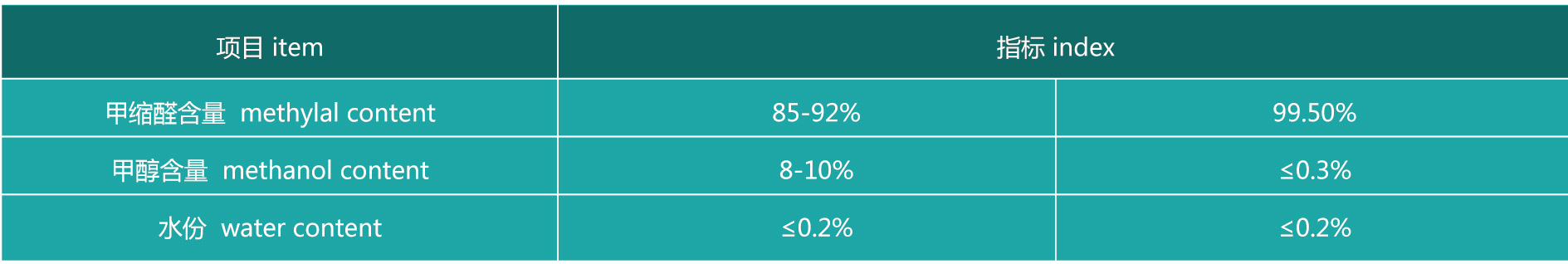

Product Quality

- About Dolton & Helipont

- Formaldehyde production technology

- DMMn production technology

- Paraformaldehyde production technology

- Methylal production technology

- Hexamine production technology

- Acetaldehyde production technology

- Pentaerythritol production technology

- Trimethylolpropane production technology

- Neopentyl glycol production technology

- Trimeraldehyde production technology

- 1, 4-cyclohexane dimethanol CHDM production technology

- EPP production technology

- Production technology of concentrated formaldehyde made from dilute formaldehyde