Pentaerythritol products generally include pentaerythritol (PE), dipentaerythritol (DPE) and tripentaerythritol (TPE). Different grades of products have different uses. It is generally considered that dipentaerythritol and tripentaerythritol are high-grade series products, mainly used to synthesize high-grade coating and lubricating oil.

Pentaerythritol is mainly used in coating industry in China. It can be used to produce alkyd resin coating, which improves the hardness, luster and durability of coating film. It is also used for color paint, varnish and printing ink required by the raw materials of rosin, and can be made of dry oil, smouldering paint and fang air lubricants. The fatty acid ester of pentaerythritol is a highly effective lubricant and PVC plasticizer, and its epoxy derivative is the raw material for the production of non-ionic surfactants. Pentaerythritol is easy to form complex with metals and is also used as a hard water softener in detergent formulations. In addition, it is also used in medicine, pesticides and other production.

Tetra-alcohol molecules contain four equivalent hydroxymethyl groups and have a high symmetry, so they are often used as raw materials for the production of multi-functional compounds, for example, the production of pentaerythritol triacrylate (PETA), etc.

CH3CHO+4HCHO+NaOH→C(CH2OH)4+HCOONa

The reaction is carried out in two steps. In the first step, three molecules of formaldehyde and one molecule of acetaldehyde are reacted by alder to produce trimethylated acetaldehyde:

CH3CHO+3HCHO→C(CH2OH)3CHO

Then trimethylol acetaldehyde reacts with formaldehyde in Conicharo to be reduced to pentaerythritol, formaldehyde is oxidized to formic acid, and formic acid forms sodium formate in sodium hydroxide medium.

C(CH2OH)3CHO+HCHO+NaOH→C(CH2OH)4+HCOONa

The reaction mechanism can be expressed as follows.

CH3CHO+HCHO→HOCH2CH2CHO→HC(CH2OH)2CHO→C(CH2OH)3CHO→C(CH2OH)4+HCOONa

Pentaerythritol process flow chart

2, Mother liquid and material were separated by continuous belt vacuum centrifuge.

3, Plenty of product varieties, low consumption, by-product recovery completely, small pollution, high degree of automation and mechanization.

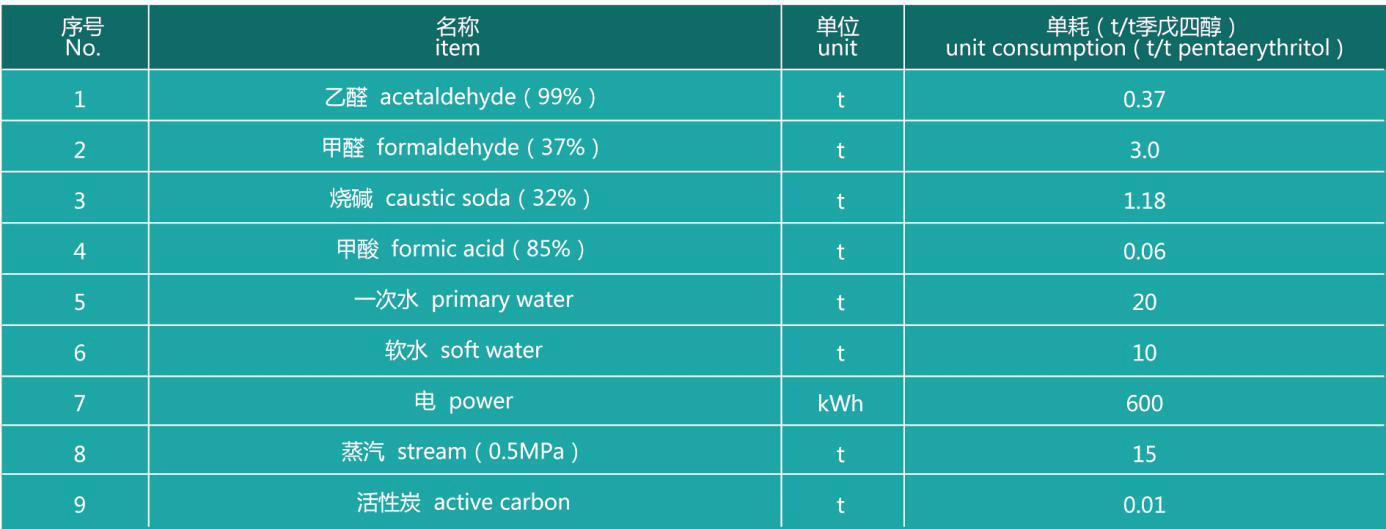

Main raw material consumption

Product Quality

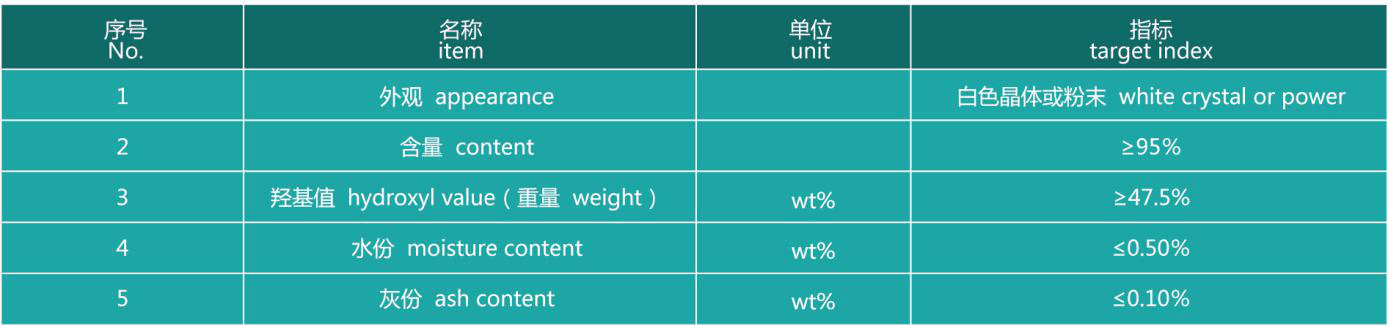

Specifications of Pentaerythritol products(95%)

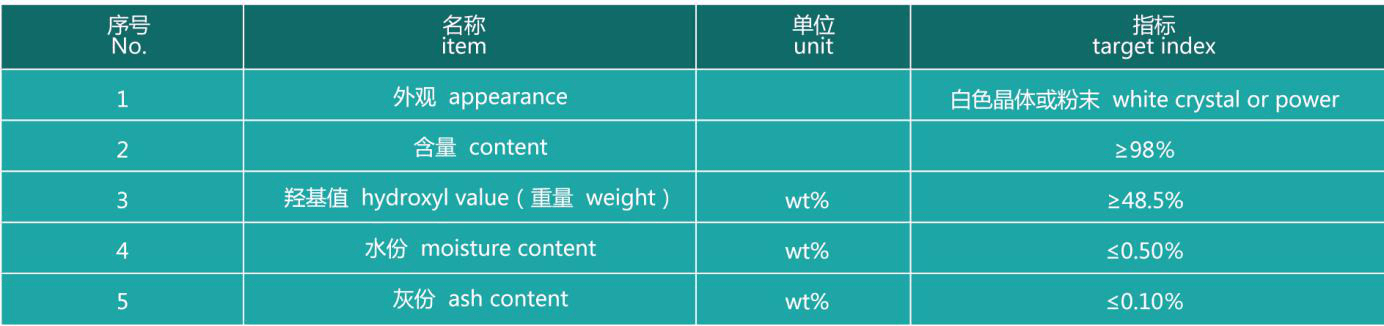

Pentaerythritol product specifications (98%)

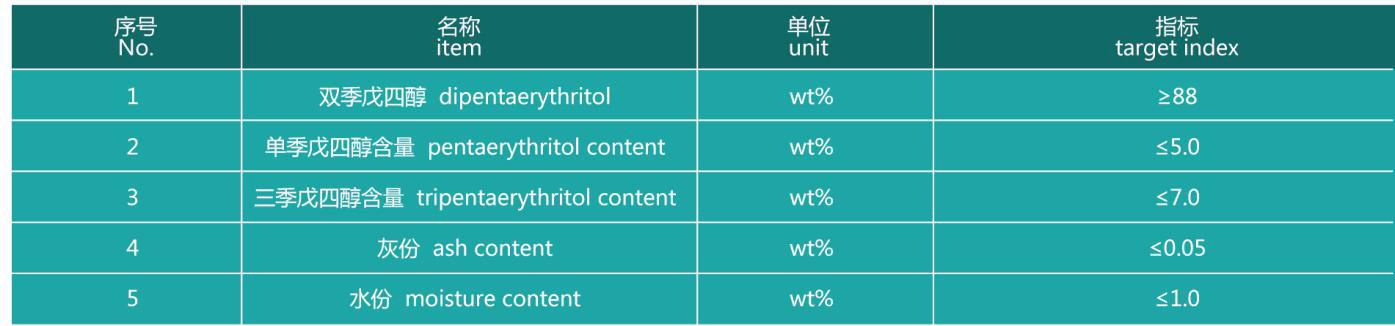

Dipentaerythritol product specifications

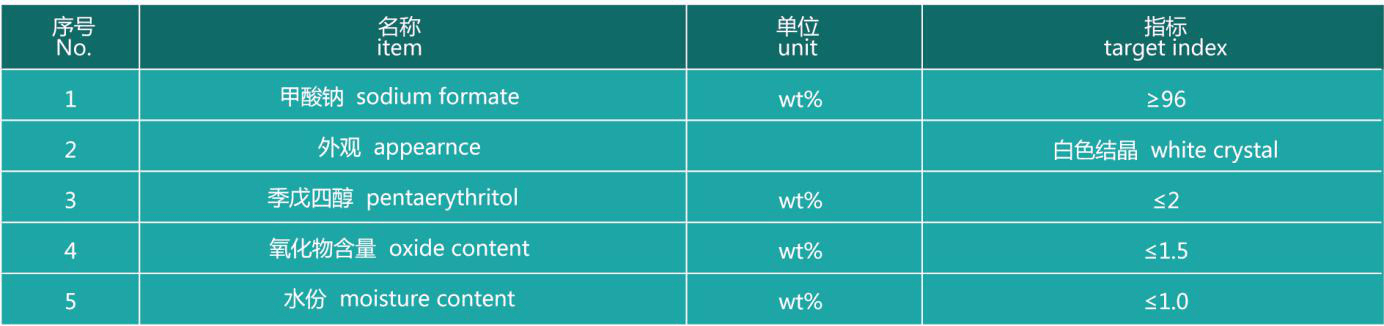

Sodium formate product specifications

- About Dolton & Helipont

- Formaldehyde production technology

- DMMn production technology

- Paraformaldehyde production technology

- Methylal production technology

- Hexamine production technology

- Acetaldehyde production technology

- Pentaerythritol production technology

- Trimethylolpropane production technology

- Neopentyl glycol production technology

- Trimeraldehyde production technology

- 1, 4-cyclohexane dimethanol CHDM production technology

- EPP production technology

- Production technology of concentrated formaldehyde made from dilute formaldehyde