Trimeraldehyde is formaldehyde cricoid trimer, is very stable crystal, used in engineering plastics poly formaldehyde and other chemical intermediates, the disinfectant, etc, also can be used in the production of epoxy resin, bisphenol A catalyst, which is the main raw material of daily cosmetics cold perm and hair removal agent, it can also be used for synthesis of transparent plastic and organic antimony, organic tin heat stabilizers such as raw material thioglycolic acid, diisooctyl. The reagent product is a sensitive reagent for testing iron, molybdenum, silver, tin and other metal ions. As an important organic chemical raw material, tripolyformaldehyde can also be used as an inhibitor of copper sulfide and iron sulfide minerals in mineral processing.

Technological Process

Currently trimeraldehyde production process is divided as: sulfuric acid catalytic synthesis in liquid phase, gas phase synthesis of formaldehyde, catalytic synthesis of ionic liquids, solid acid catalytic liquid-phase synthesis (heteropoly acid/strongly acidic cationic exchange resin). At present most manufacturers adopt concentrated sulfuric acid catalytic synthesis in liquid phase, and we are using solid acid catalytic liquid-phase synthesis, process diagram is as follows:

2, Formaldehyde conversion rate is high, with good product quality.

3, Small amount of waste water, simple treatment.

Main raw material consumption

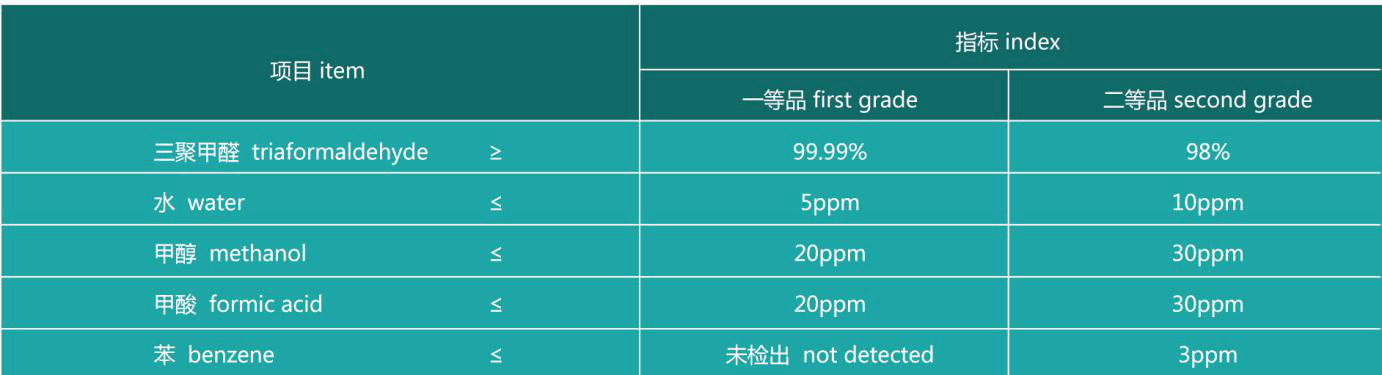

Product Quality

- About Dolton & Helipont

- Formaldehyde production technology

- DMMn production technology

- Paraformaldehyde production technology

- Methylal production technology

- Hexamine production technology

- Acetaldehyde production technology

- Pentaerythritol production technology

- Trimethylolpropane production technology

- Neopentyl glycol production technology

- Trimeraldehyde production technology

- 1, 4-cyclohexane dimethanol CHDM production technology

- EPP production technology

- Production technology of concentrated formaldehyde made from dilute formaldehyde