PDF Download

PDF Download

| No. | Item | Index | Remarks |

|---|---|---|---|

| 1 | Paraformaldehyde content | 92-96%w/w | Normally92% |

| 2 | Formic acid | <0.03% | |

| 3 | Melting range | 120-170℃ | |

| 4 | Ash content | <100ppm | |

| 5 | Appearance | White powder | |

| 6 | Methanol content | <1wt% | |

| 7 | Free water | <8wt% | |

| 8 | Iron content | <2ppm |

2.Raw material specification

| No. | Item | Specification |

|---|---|---|

| 1 | Formaldehyde | 50.0%wt |

| 2 | Desalted water | Conductivity no more than 10μs/cm,P≥0.3mpa |

| 3 | Steam | 0.4MPa |

| 4 | Steam | 0.8MPa |

| 5 | Electricity | 380V |

| 6 | Circulating water | 30~38℃ ,0.25mpa |

| 7 | Cooling water | -1~3℃ ,0.25mpa |

| 8 | Instrumental air | 0.7MPa |

| 9 | Nitrogen | 0.7MPa |

3.Consumption index

| No. | Item | Consumption quota | Remarks |

|---|---|---|---|

| 1 | Raw material and auxiliary material | ||

| 1) | Formaldehyde(50%) | 2.665T/T | |

| 2) | Dilute formaldehyde(19%~24%) | -2.2T/T | By-product dilute formaldehyde |

| 2 | Utilities | ||

| 1) | Circulating water t≤32℃,△t=10℃ | 288T/T | |

| 2) | Dynamic electricity(380V) | 280kWh/T | |

| 3) | low pressure steam P=0.4MPa(G) | 1.30T/T | |

| 4) | low pressure steam P=0.8MPa(G) | 0.90T/T | |

| 5) | cooling water-2℃,△t=5℃ | 120T/T | |

| 6) | soft water | 0.2T/T | |

| 7) | instrumental air P=0.7MPa(G)) | 48Nm3/T | |

| 8) | Nitrogen P=0.7MPa(G) | 99Nm3/T |

| Project | Model and parameter | Production lines | Finish date |

|---|---|---|---|

| Jiangsu Sanmu bloc Co. Ltd. | 20000tpa paraformaldehyde plant | 1 | 2014.4 |

Overview - Spray Dryer Process

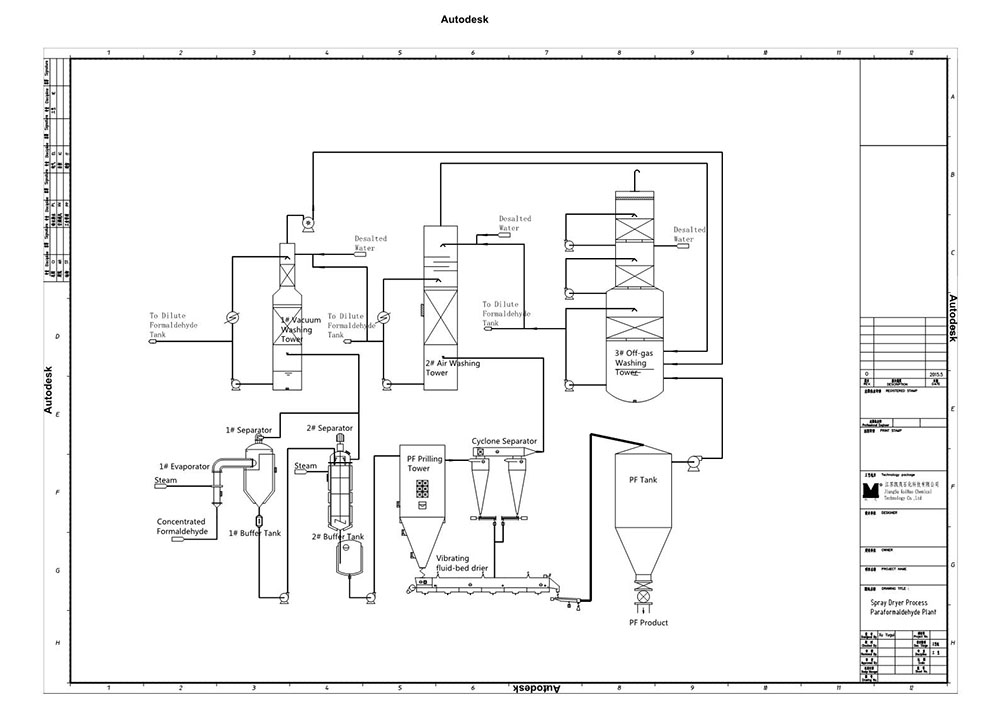

Formaldehyde (HCHO) is with chemical activity and strong reaction capacity, and it can have reaction with acetic acid and Propanoic acid, making important chemical intermediates, such as acrylic acid and methacrylic acid. HO(CH20)nH is the product formed from formaldehyde solution dehydration and condensation. It is divided into 2 kinds, including paraformaldehyde with low polymerization degree (polymerization N is 2-8) and paraformaldehyde(polymerization N is 8-100). Paraformaldehyde is the solid powder, convenient for storage and transportation, and it is widely applied in chemical compounds and other industrial field such as chemistry and pharmacy, it is the excellent replacement for industrial formaldehyde. But paraformaldehyde itself has no chemical activity. Only by depolymerizing paraformaldehyde into single formaldehyde, can it be used for reaction. In addition, in the storage process, formaldehyde can be easily polymerized, and it has to be depolymerized for being made full use of.1、PID description for paraformaldehyde with spray drying process

(1). First-efficiency condensation: 50%-55% formaldehyde solution comes from the bottom of the first- efficiency evaporator; the theory for first-efficiency evaporator is climbing film evaporation. With the certain temperature controlled in the first-efficiency evaporator, and the pressure controlled to be negative pressure, the created gas phase and liquid phase material come together into first-efficiency evaporator for vacuum liquid-gas separation (pressure is the negative pressure), the gas is the mixed gas of water and formaldehyde steam, and it comes to 1# absorber for absorption, getting the dilute formaldehyde solution. The liquid is the high concentration formaldehyde solution, and it will be pumped into second-efficiency separator for further condensation.

(2).Second-efficiency condensation: The high concentration formaldehyde solution from the first-efficiency evaporation is pumped into the top of the second-efficiency separator; the second-efficiency separator theory is the falling film evaporation. With the certain pressure controlled in the evaporator and pressure controlled to be negative pressure. The water get evaporated and condensed during the high concentration formaldehyde flowing downwards along with wall, owing to the gravity action. After separation, the liquid is the 85% formaldehyde solution. The off gas of the separator is mainly water and formaldehyde steam. It comes into 1# absorber for absorption, getting dilute formaldehyde solution.

(3).Spray drying: 85% high concentration formaldehyde solution spurts from the nozzle, and it is condensed into prilled paraformaldehyde solid in the spraying cooling tower with temperature of 0~50℃. N2 air supply system is set in the spraying cooling tower, and when the off gas comes into cyclone collecting materials, the discharging gas comes into 2# absorber for formaldehyde absorption. The collected paraformaldehyde solid and the condensed prilled paraformaldehyde solid come together into fluidized-bed dryer for further drying.

(4). fluidized-bed drying:The solid paraformaldehyde from the spraying cooling tower and cyclone dust collector comes into fluidized-bed drying. The fluidized bed dryer has three sections, separately controlled in different temperature range. Via drying and dewatering, 92% paraformaldehyde solid can be obtained. Via hoist, it will be transported to storage tank for storage. The fluidized-bed also has N2 air supply system, and the off gas after cyclone separation comes into 2# absorber for formaldehyde absorption.

(5). Off-gas absorption:The Paraformaldehyde project has set 3 sets of absorbers; the No. is separately 1#, 2# and 3#.

1# absorber absorbs the off-gas from first-efficiency and second efficiency condensation. The off gas of spray granulation via cyclone for dedusting, and the fluidized-bed drying off gas, comes into 2# absorber for formaldehyde absorption. The waste gas of paraformaldehyde storage tank, the off gas of 1# absorber, the off-gas of 2# absorber and waste gas of formaldehyde tank yard are all sent to 3# absorber for formaldehyde absorption. The off gas discharged from 3# absorber comes into off-gas furnace of formaldehyde project for burning.

The absorption liquid of 3# absorber is the desalted water or process waste water from other plants( such as waste water of formaldehyde plant) absorption liquid of 2# absorber is the water discharged from 3# absorber, and the absorption liquid of 1# absorber is the water discharged from 2# absorber. In 1# absorber, 19%-28% dilute formaldehyde solution can be obtained.

2、Main equipment description:

When designing the spraying tower, that the spraying pressure, the spraying angle, the diameter of spraying tower, the height and time of material staying in the tower, the temperature and flowing speed of cooling media can all have big effects to the product quality. For example, high concentration formaldehyde solidification temperature is connected with the tower height, and the too high temperature of spraying will affect the granule to be soft and tack, effecting the continuous operation, thus the design of spray drying equipment is an organic and systematic project, a complete copy is not ensured to be a success.(1). Spraying and prilling tower

When designing the spraying tower, all the spraying pressure and angle, the diameter of tower and height, and the time of material staying in tower and cooling media temperature and flowing speed affect the product quality. For example, high concentration formaldehyde solidification temperature is connected with the tower height, and the too high temperature of spraying will affect the granule to be soft and tack, effecting the continuous operation, thus the design of spray drying equipment is an organic system and the new type prilling technologies of Kaimao are with big capacity and the single equipment capacity can reach 30000tpa and with good product performance. The dissolution time can reach the international standard.

(2).Fluidized-bed dryer

For paraformaldehyde, the drying part is the core of the spraying granule technology, for the bad drying environment will result inferior product. In the drying process of paraformaldehyde, the control on the fluidized state and the stay of product granularity has mutual influence and mutual relations of contradictions, however the fluidized-bed dryer of Kaimao has well solved this problem.(3).Concentrator

The concentrator needs to improve the formaldehyde concentration in a short time, and ensure the non-polymerization. The concentrator self researched by Kaimao has two sections for condensation. The core technology is the scraper falling film technology. The scraper falling film concentrator of Kaimao is a single set whose area can reach 40m2, which is the falling film evaporator with the biggest area in China. It is characterized with reasonable structure, uniform distribution, highly efficient evaporation rate and easy operation. This technology fills the emptiness of this field in China.3、Process features:

At present the traditional rake drying process has been adopted by most of the paraformaldehyde plants, with high energy consumption, the difficultly controlled production process, the high polymerization, the low output, bad operating environment, serious pollution and high costs. For spray dryer process, the formaldehyde content can be controlled in 92~96%, with porosity, good water solubility and short depolymerization time. Under the condition of paraformaldehyde depending on import at present, Our Company Jiangsu Kaimao has brought the new paraformaldehyde production plants, which are very popular. The features of these plants are as below”(1).By adopting the advanced concentration and drying process, the product is with good quality, low costs and consumption, mature technology and completely localization of production plants, Which makes it competitive to the biggest PF manufacturer in the world.

(2).In the production technology, we attach importance to the research and development of formaldehyde condensation system, the spraying tower design, and the spraying head design and catalyst selection.

(3).The recycling dilute formaldehyde of the formaldehyde condensation system is to make methylal, and then further turns into formaldehyde solution with more higher additional value, and the continuous circulation use is the most important characteristic, and at the same time the low consumption of the product and the low costs are very competitive, when compared with the domestic industry.

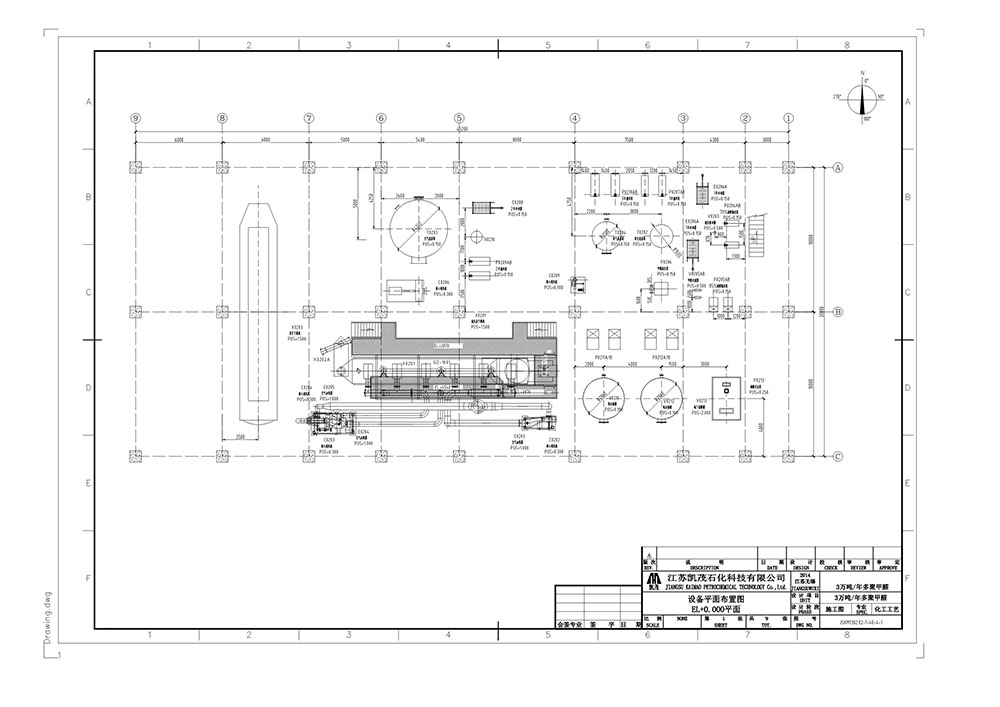

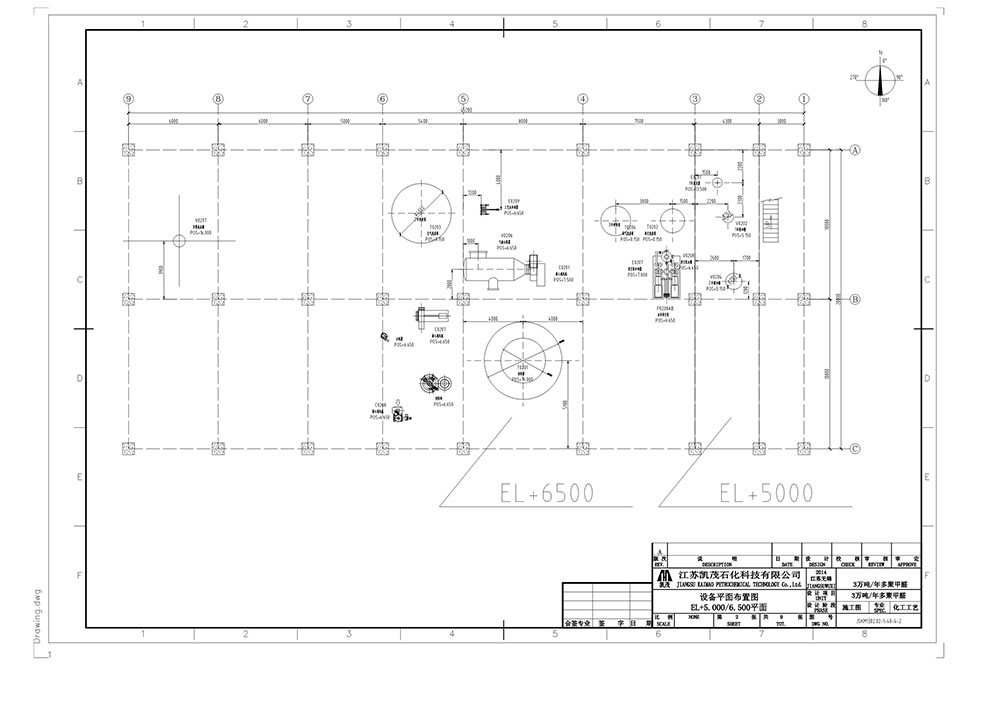

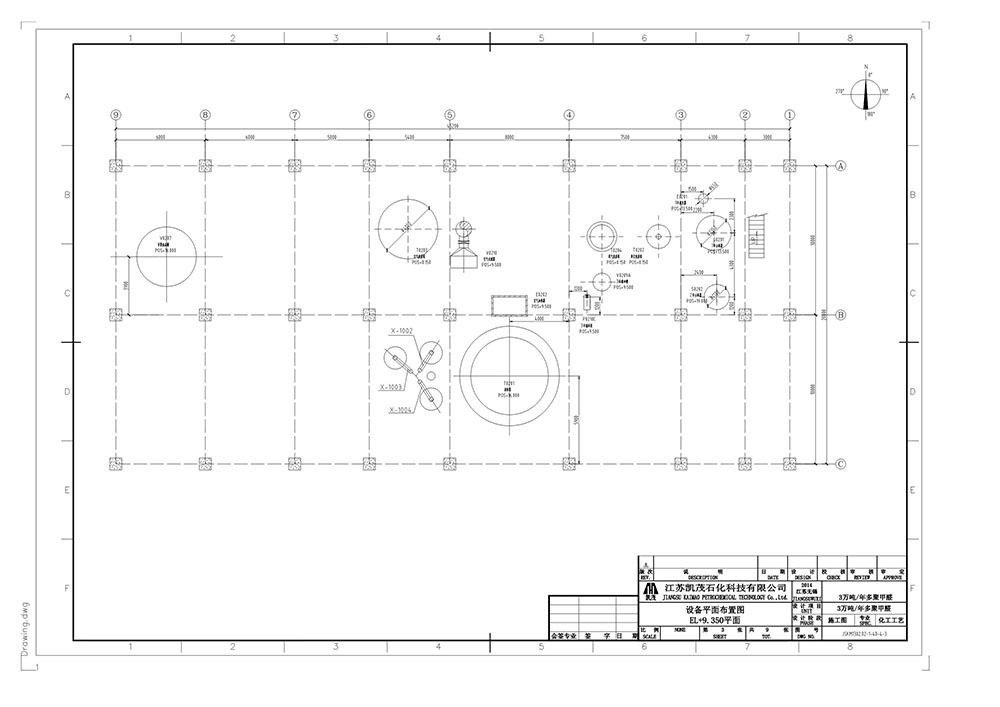

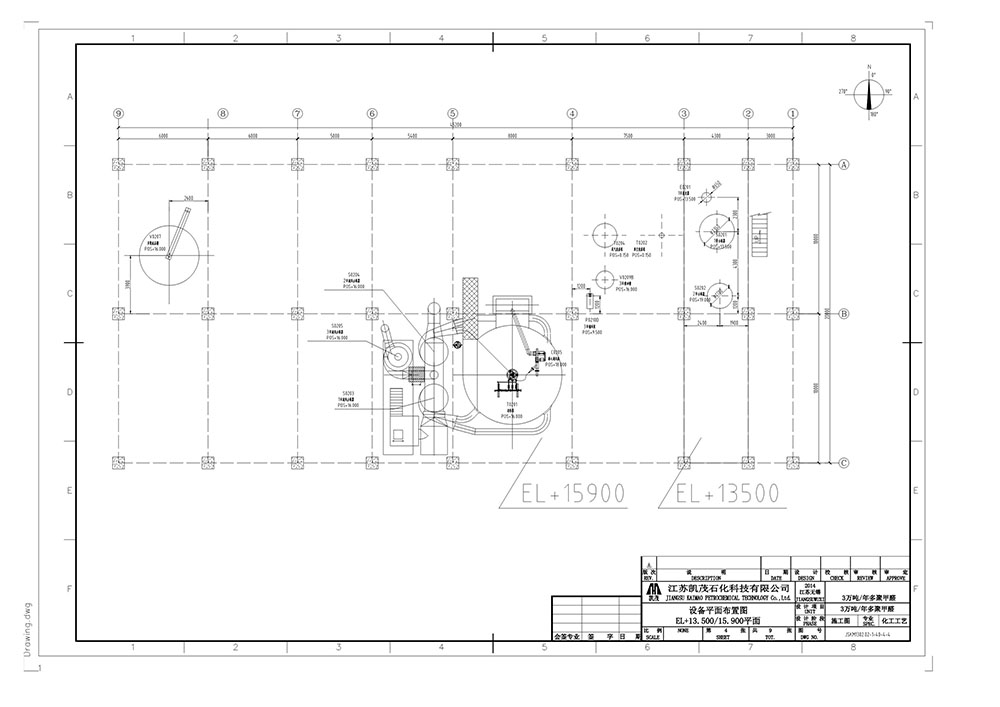

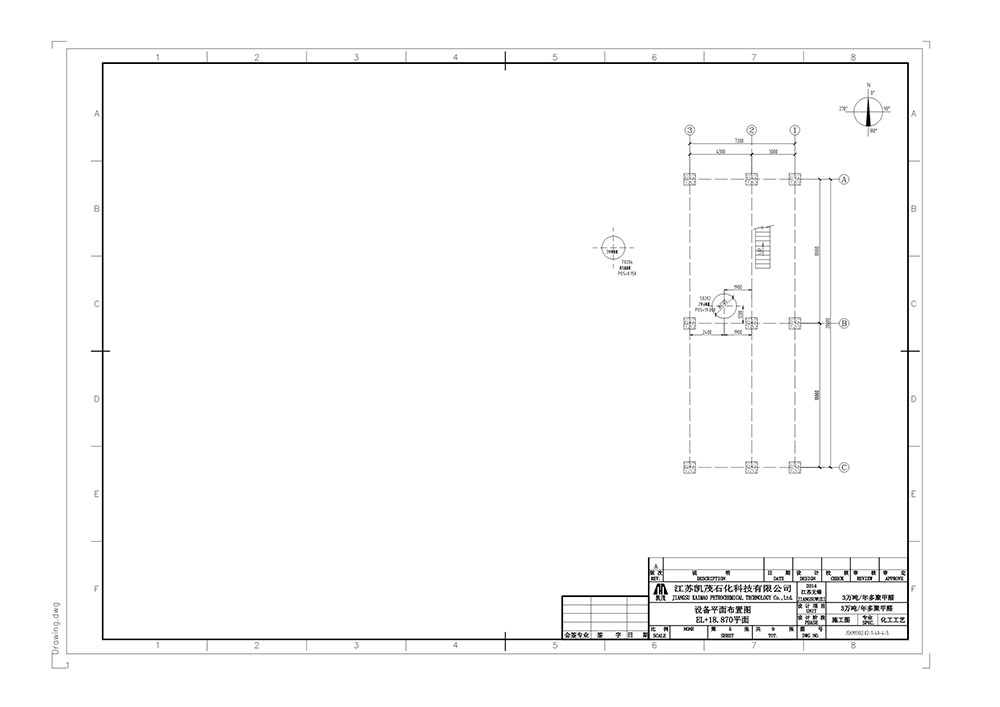

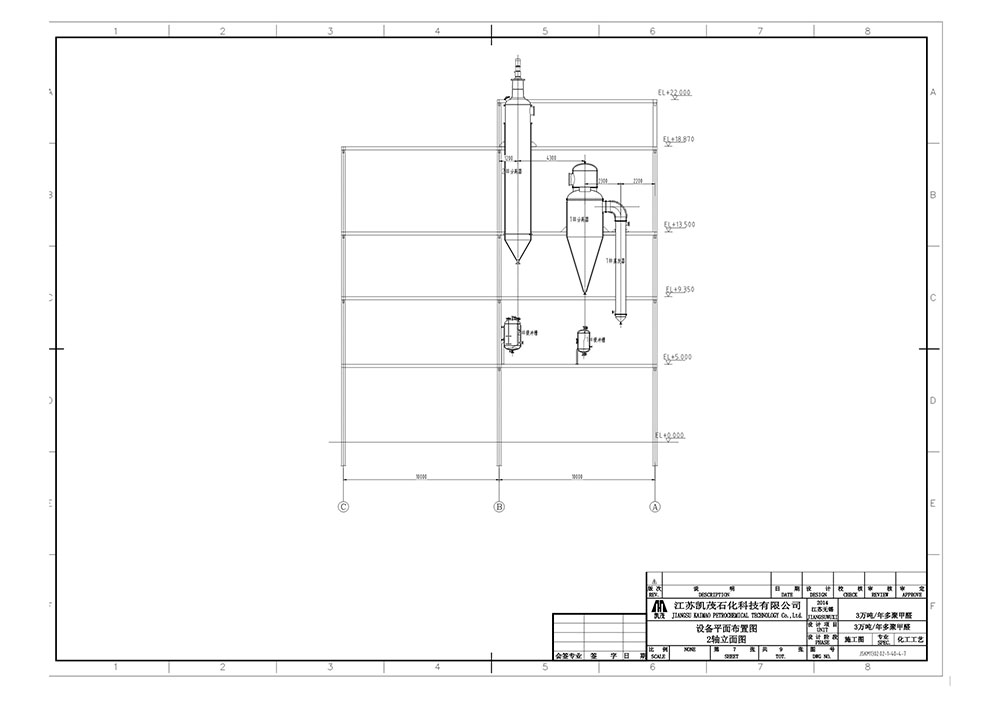

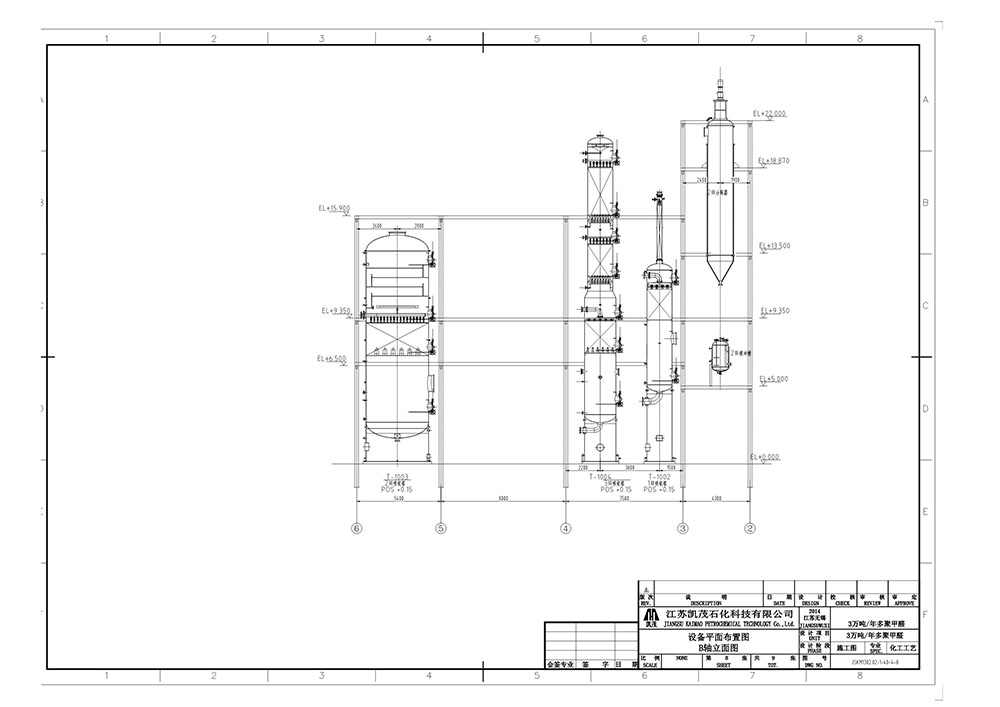

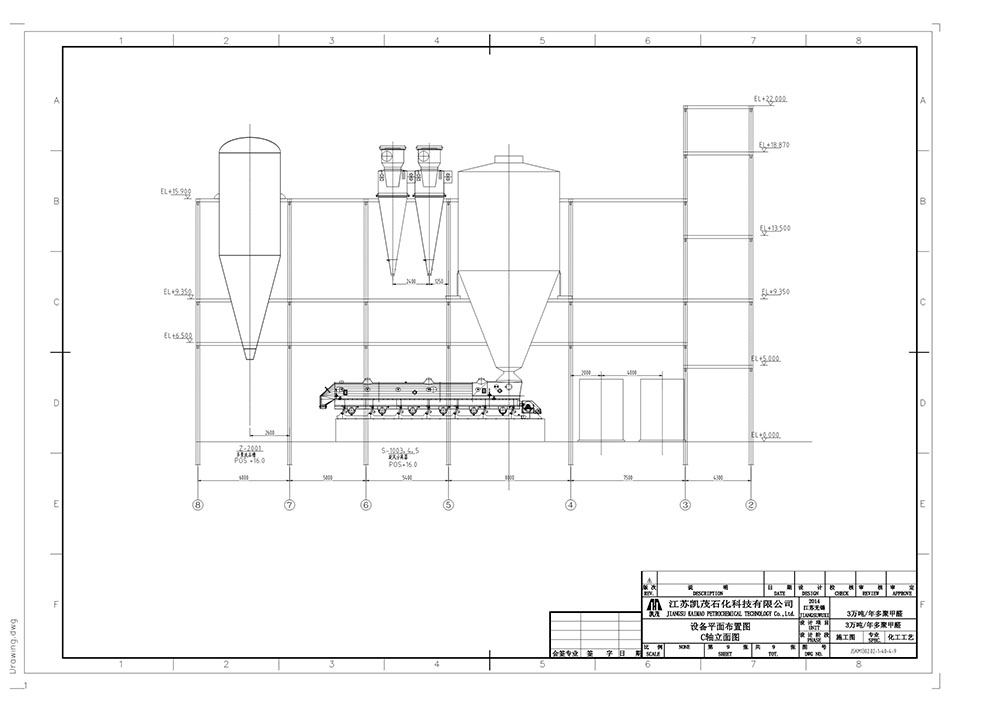

设备布置图

设备布置图